The Lincoln Electric® COOPER™ Cobot

The Lincoln Electric® COOPER™ Cobot robotic welding system designed for ease of use and flexibility, making automation accessible to a wide range of industries. It offers, user-friendly programming, multiple industry integration, a portable and compact size, and the ability to integrate with advanced welding systems.

Click here to view more detail

Click here to view less detail

Collaborative Robot Welding Solution:

The Lincoln Electric® COOPER™ Cobot robotic welding system features simplified programming with the new tablet-based teach pendant and the ability to teach at the torch. Simply move the cobot’s arm with your hand to the weld start and finish. These cobot welding systems are built for the industrial space and has access to Lincoln Electric’s highest productivity weld programs allowing you to maximize productivity.

Ideal For:

- High-mix job shops

- Repair and remanufacturing

- Part resurfacing and reconditioning

- Roof and bridge trusses

- Mechanical contractors and pipe shops

- Agricultural equipment

- Steel fabricators and metal service centers

- Training and educational programs

The COOPER™ Cobot robotic welding system easily moves to parts that need to be welded and can be safely operated in tandem with your production staff.

What’s Included:

- FANUC® CRX with tablet based TP or ABB® GoFa collaborative arc welding robot arm with robust controller

- AutoDrive® 4R100 wire feeder (air cooled) or AutoDrive 4R220 wire feeder (water cooled)

- Power Wave® R450 welder

- Fixed welding table (on options with cart)

- Heavy duty casters (on options with cart)

- Stabilizing kickstand (on options with cart)

- The Cooper™ App

- CSA approval for Canada

System Options:

- Wire reel assembly kit

- Modular tooling table and components (on options with cart)

- Mag-switch base for multiple mounting options (on options with cart)

- Integrated fume extraction (on options with cart)

- JumpStart onsite startup package – 2-day coaching and preparation session with cobot subject matter expert

Benefits:

- Increase Productivity

- Increase productivity with a collaborative robot system that your operators can work alongside with.

- Simplified Programming

- The simplified, icon-based programming is designed for straightforward, user-friendly operation.

- Teach At The Torch

- Designed for an operator at any level of experience with robotics, the COOPER™ Cobot system allows for teaching at the torch.

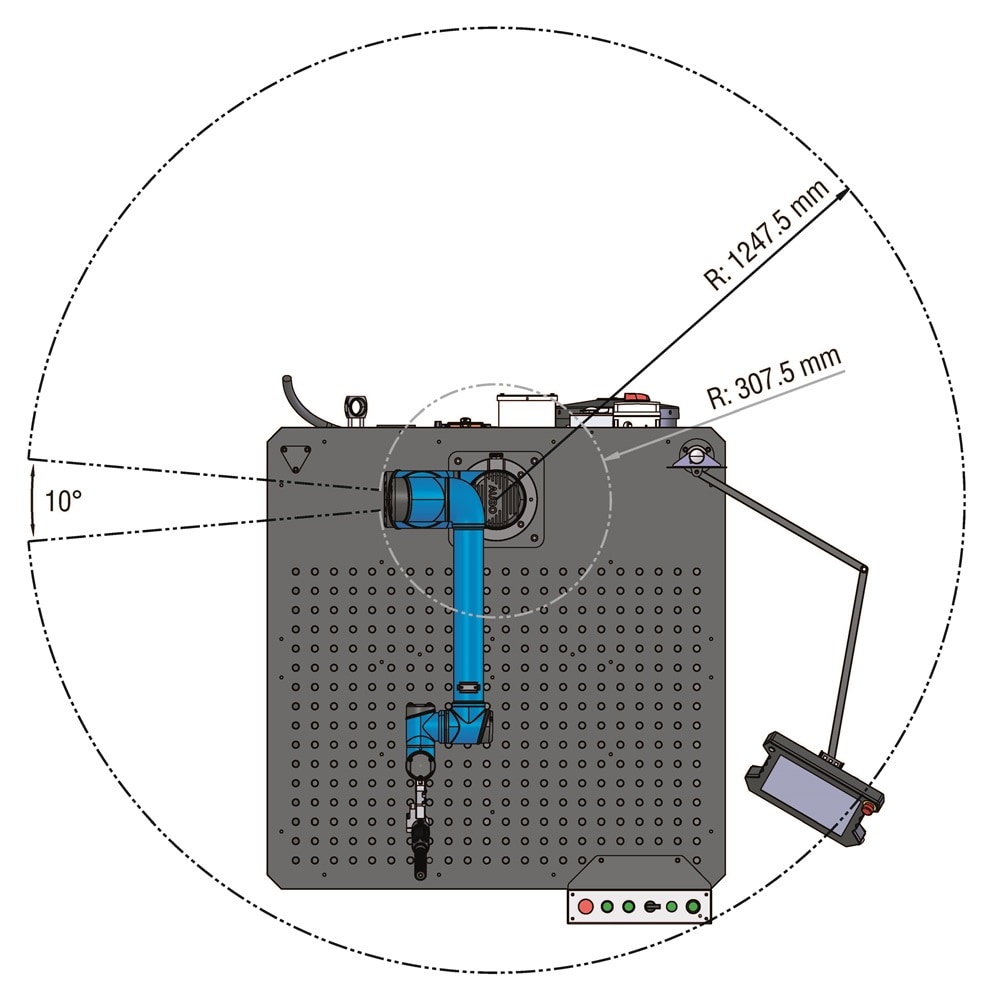

- Flexible Work Zone

- The adaptable and easy to move system allows you to bring the cobot to every part. Providing greater flexibility and more freedom to automate your welding throughout your facility.

- Small Footprint

- Mobile, flexible system with small footprint on the shop floor.

Touch Panel Tablet Teach Pendant:

The Cooper™ App will help you quickly program and produce quality welds. On-screen steps guide users through the weld programming process easily. Whether your fabrication requires a standard singlepass liner weld or structural steel multi-pass welds, the Cooper™ App can help. Lincoln Arc.

Welding Plug-In:

- Receives input directly from pushbuttons at the integrated torch, automatically recording points on the timeline.

- Operator can clearly see specific arc start/end points on timeline and “tap” to change weld parameters.

Available Models:

Air Cooled

| Part Number | Lincoln

Part Number | Model | Dimensions | Robotic Arm

Payload Dimensions | Robotic

Arm Reach | System Weight | Fixed Table

Work Envelope | Fixed Table

Payload |

|---|

| LINAD2489-8 | AD2489-8 | Cooper CRX-10iA/L air cooled

welding cobot cart | 1,752.6 mm x 889 mm x 2,032 mm

(69 in x 35 in x 80 in) | 10 mm

(22 in) | 1,418 mm

(55.8 in) | 407 kg

(895 lb) | 1,117.6 mm x 889 mm

(44 x 35 in) | 226 kg

(500 lb) |

| LINAD2489-6 | AD2489-6 | Cooper CRX-251iA air cooled

welding cobot cart | 1,752.6 mm x 1,174 mm x 2,662 mm

(69 in x 46 in x 105 in) | 25 mm

(55 in) | 1,889 mm

(74.4 in) | 905 kg

(1,995 lb) | N/A | N/A |

| LINAD2501-1 | AD2501-1 | Cooper 15000 GoFa air cooled

cobot cart | 1,752.6 mm x 889 mm x 2,032 mm

(69 in x 35 in x 80 in) | 5 mm

(11 in) | 950 mm

(37.4 in) | 475 kg

(1,047.2 lb) | 1,117.6 mm x 889 mm

(44 x 35 in) | 226 kg

(500 lb) |

Water Cooled

| Part Number | Lincoln

Part Number | Model | Dimensions | Robotic Arm

Payload Dimensions | Robotic

Arm Reach | System Weight | Fixed Table

Work Envelope | Fixed Table

Payload |

|---|

| LINAD2489-10 | AD2489-10 | Cooper CRX-10iA/L water cooled

welding cobot cart | 1,752.6 mm x 889 mm x 2,032 mm

(69 in x 35 in x 80 in) | 10 mm

(22 in) | 1,418 mm

(55.8 in) | 522 kg

(1,150 lb) | 1,117.6 mm x 889 mm

(44 x 35 in) | 226 kg

(500 lb) |

| LINAD2489-7 | AD2501-7 | Cooper CRX-251iA water cooled

welding cobot cart | 1,752.6 mm x 1,174 mm x 2,662 mm

(69 in x 46 in x 105 in) | 25 mm

(55 in) | 1,889 mm

(74.4 in) | 1,005 kg

(2,216 lb) | N/A | N/A |

Aluminum

| Part Number | Lincoln

Part Number | Model | Dimensions | Robotic Arm

Payload Dimensions | Robotic

Arm Reach | System Weight | Fixed Table

Work Envelope | Fixed Table

Payload |

|---|

| LINAD2489-14 | AD2489-14 | Cooper CRX-10iA/L aluminum

welding cobot cart | 1,752.6 mm x 889 mm x 2,032 mm

(69 in x 35 in x 80 in) | 10 mm

(22 in) | 1,418 mm

(55.8 in) | 531 kg

(1,170 lb) | 1,117.6 mm x 889 mm

(44 x 35 in) | 226 kg

(500 lb) |

| LINAD2489-16 | AD2489-16 | Cooper CRX-25iA aluminum

welding cobot cart | 1,752.6 mm x 1,174 mm x 2,662 mm

(69 in x 46 in x 105 in) | 25 mm

(55 in) | 1,889 mm

(74.4 in) | 1,005 kg

(2,216 lb) | N/A | N/A |

Click Here to Go to the Top