Partner with Linde Canada for Dry Ice Blasting Solutions

Linde Canada pairs premium-quality dry ice with cutting-edge blasting equipment to empower businesses across industries with clean, efficient, and sustainable solutions. Backed by over 70 years of technical expertise, we are trusted partners in delivering reliable service, tailored applications, and robust machine rental programs.

Get piece of mind with Canada’s largest dry ice production and distribution network.

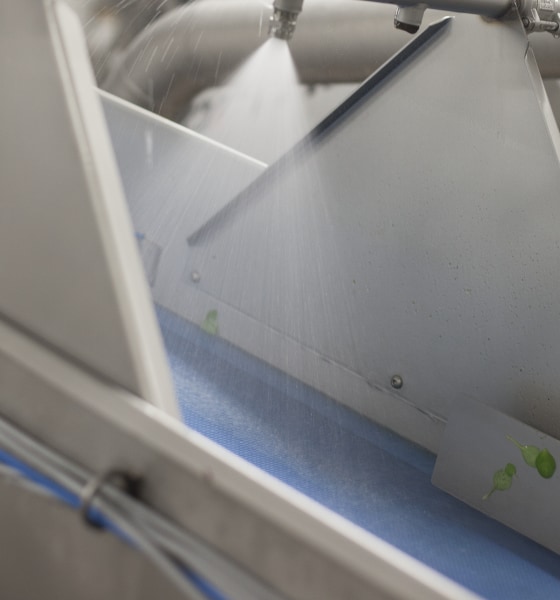

Linde Canada's dry ice blasting machine rental program offers a cost-effective way to bring this revolutionary process into your daily operations, replacing labour-intensive chemical methods with a safer, faster alternative.

Transform Your Cleaning Operations Today

Dry ice blasting unlocks cutting-edge efficiency, versatility, and safety suitable for industries from food processing and pharmaceuticals to aerospace, manufacturing, and historic preservation. Whether you’re replacing chemical scrubbing, reducing downtime during routine maintenance, or tackling tough contaminants like grease or mould, this innovative process delivers results that set new standards for cleanliness and operational success.

Contact your nearest Linde Canada branch by visiting www.lindecanada.ca/store-locator or by calling 1-800-225-8247. Our experts will be happy to assist you with all your dry-ice blasting needs.

It’s time to elevate your cleaning practices, improve efficiency, protect your equipment and your reputation with Linde Canada’s premium dry ice blasting solutions.