Quick Answers to Common Questions

How do cobots improve productivity?

They maintain consistent weld quality, reduce downtime, and free skilled welders for high-value work.

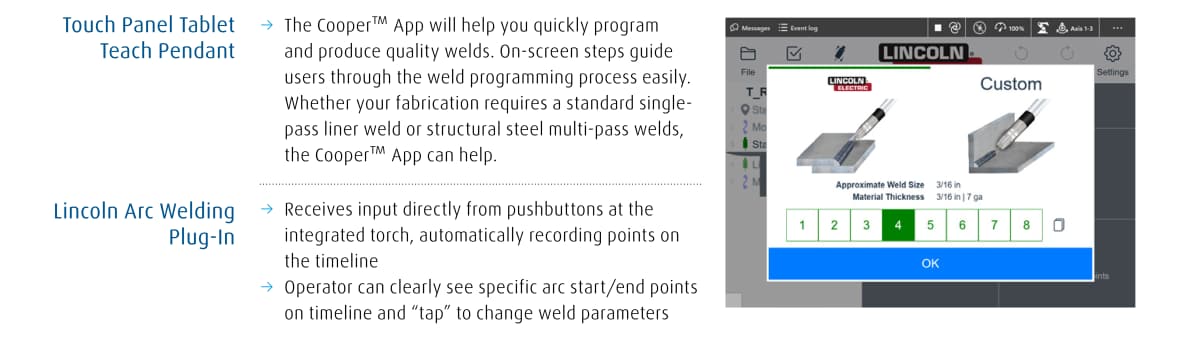

Do cobots require complex programming?

No. Most cobots feature teach-by-touch programming and intuitive interfaces.

Are cobots suitable for small shops?

Yes. Cobots have a compact footprint and can be easily integrated into existing workflows.

What power source options are available for welding cobots?

Welding cobots are compatible with a wide range of power sources from leading manufacturers, allowing for flexible integration based on your shop’s needs.

What is the maximum reach of a cobot arm?

Cobots are available with arm reaches of up to 74.4 inches, providing ample coverage for various welding applications.

Can welding cobots be configured without a work table?

Yes. Cobots are available in multiple configurations, including models without a work table, to suit different workspace layouts and operational requirements.

Is multi-pass welding possible with a cobot?

Yes. Many cobot systems support multi-pass welding, enabling high-quality welds for thicker materials and complex joints.

Do welding cobots offer touch sensing capabilities?

Yes. Several cobot models are equipped with touch sensing features to enhance precision and adaptability during welding operations.

Are cobots equipped with seam tracking technology?

Yes. Many collaborative welding robots include seam tracking functionality to maintain accurate weld paths and improve overall consistency.